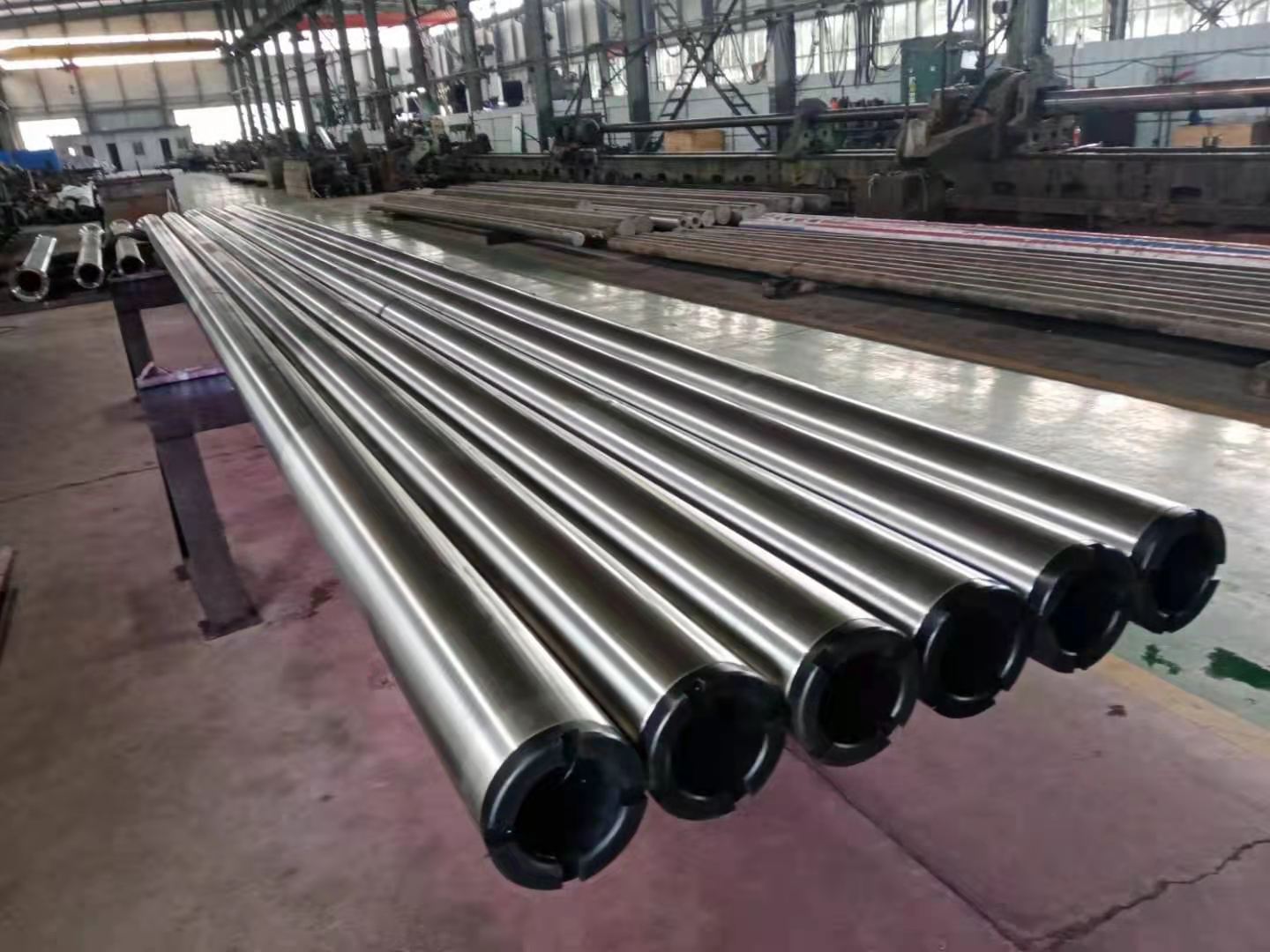

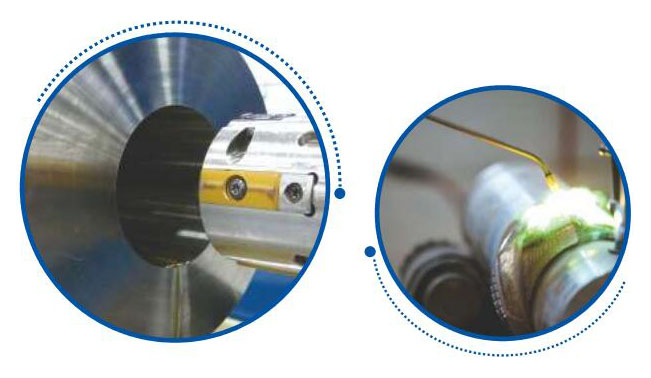

The company has a complete production process, with a complete quality control system and R & D team. And there are a number of industry senior professionals to join the team. The production process includes melting (EAF + LF + AOD + ESR), Free forging ( 2T/3T/5T electro-hydraulic hammer) and Precision forging (750T/1300T/1800T GFM forging machine), machining, deep hole drilling, threading machine, milling groove machine, and heat treatment processing; with a complete set of testing means: OBLF desktop direct reading spectrometer, oxygen and nitrogen meter, ultrasonic instrument, hardness tester, Magnetic conductivity detector and a full set of mechanical properties testing equipment such as tensile testing machine and impact testing machine. We ensure that all products strictly comply with the quality standards to meet the requirements of all customers.

-

Quality Assurance

-

Production

-

Service

-

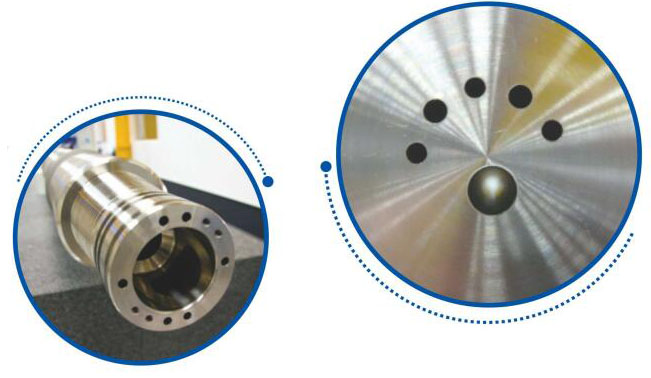

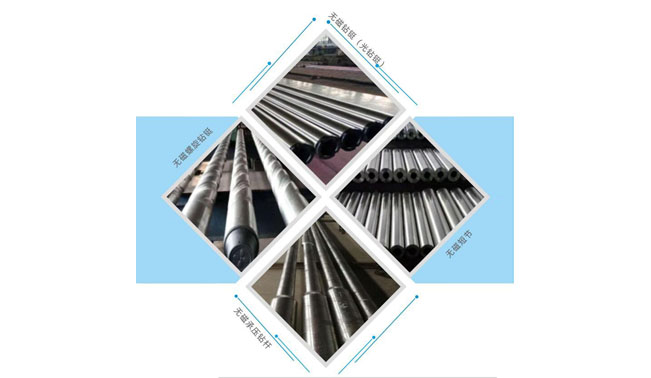

無磁產(chǎn)品

Resistance to corrosion -

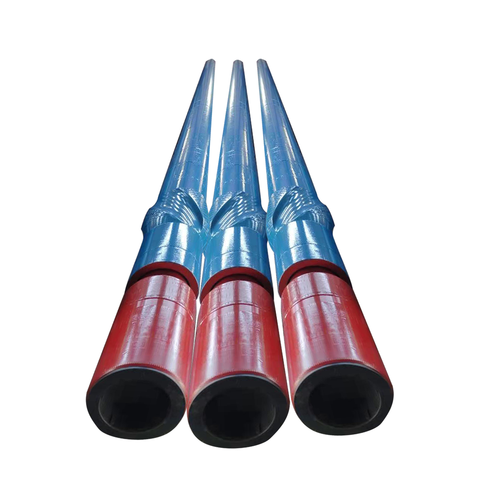

石油鉆具

Low permeability

-

Sales contact:

15922134617 Mr Mao

-

Technical director:

13511685966 Mr li

Email:Sam.mao@zjherui.com